Ecoremedy® uses a proprietary advanced gasification process, developed by decades of fine-tuning, to process waste into:

For an animation of Ecoremedy technology, visit our Technology Page

Ecoremedy focuses on wastes that have proven to be problematic for other carbon-conversion technologies, especially wet and sticky material commingled with dry and dusty material.

These waste materials often have the following characteristics:

Ecoremedy processes these materials without the need for supplemental fuels like propane, natural gas, oil, or conventional biomass like woodchips. In terms of moisture content, the minimum is 17% solids (83% moisture content), with 60-65% solids (35-40% MC) being ideal.

Between our R&D facility, pilot projects, and commercial projects, Ecoremedy has successfully processed the following waste streams:

If you are interested in an Ecoremedy solution for a waste stream not listed here, please contact us for feedstock testing.

When sewage sludge is dewatered and undergoes rigorous treatment, the nutrient-rich product is called biosolids.

Biosolids can be treated to various standards, including Class B, Class A, or Class EQ (exceptional quality).

Biosolids are often used for land application as fertilizer, but they can also be used as a renewable solid fuel, or further processed by Ecoremedy equipment into various forms of activated biochar for specific applications.

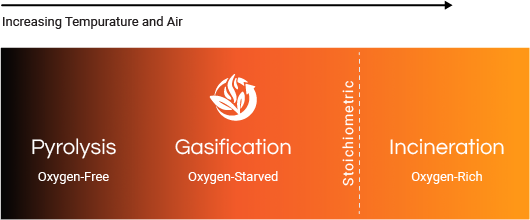

For more than half a century, gasification has been used in hundreds of installations around the world to recover energy from various hydrocarbons and waste streams.

Gasification is the process of heating the incoming material (feedstock) to a high temperature in an oxygen deficient environment. This causes the waste to break down into energy-rich syngas. The Ecoremedy process uses the constituents of the feedstock to serve as the initial stage of emission control, which self-scrubs pollutants as part of the gasification process. Ecoremedy precisely balances the combustion equation by introducing air in the secondary and tertiary chambers (the oxidizer) to combust the syngas resulting in high temperature, clean, renewable thermal energy. This energy can be in the form of steam, hot water, hot air, or even refrigeration.

The process described above is close-coupled gasification. Ecoremedy uses close-coupled gasification instead of two-stage gasification to generate pipeline-grade gas or directly fuel a generator. For information, see Can Ecoremedy generate electricity? How does Ecoremedy utilize the energy from waste?

Ecoremedy focuses on wastes that have proven to be problematic for other carbon-conversion technologies, especially wet and sticky material commingled with dry and dusty material.

For an animation of Ecoremedy technology, visit our Technology page.

For a list of all Ecoremedy projects, visit our Experience page.

Building on early success with pilot-scale biosolids gasification, Ecoremedy completed construction of its first industrial-scale biosolids project in 2019.

The Morrisville Biosolids Gasification Project processes up to 25,000 wet tons per year of dewatered biosolids from the host wastewater treatment plant and the greater Philadelphia region. For more information, visit our Morrisville Project page.

Pilot-scale testing was performed in the fall of 2010 at our R&D facility at Harrisburg Area Community College.

Ecoremedy ran a seven-day, 24-hour-per-day demonstration of poultry litter and composted biosolids for visitors from Australia. During that time, we ran the composted biosolids (approximately 45% moisture content) for three days straight. We transitioned from 100% litter to 100% biosolids over the course of three hours without stopping or retooling the equipment. We simply adjusted the feed rate and air control to the gasifier. We ran a feed rate of about 800 lbs/hr in the gasifier.

For more information about initial testing Ecoremedy performed under a partnership with Harrisburg Area Community College, visit our HACC Project page.

The system runs 24-7 using the incoming waste as the sole source of thermal energy without any supplemental fuels such as wood chips or fossil fuels.

The Ecoremedy gasification process achieves extremely clean carbon conversion. The emissions are primarily water vapor and carbon dioxide. After final scrubbing, our emissions are as clean, or cleaner, than those from combusting natural gas, and far below the most stringent state and federal standards.

Ecoremedy operations never require the storage of large volumes of waste in lagoons or stockpiles. Depending on the project, waste is either processed on-site as it is generated, or hauled in by truck and delivered to a metering bin that holds a maximum of 24 hours of waste/fuel. However, Ecoremedy projects may be colocated at an existing farm, composting facility, landfill, or other sites where waste is stored by another company under a separate permit.

Ecoremedy converts a waste liability to a multifaceted revenue stream in the form of energy and nutrient products. Renewable energy is generated and used onsite. The utilization of byproduct solids will be project specific and dependent upon regional market drivers. Dried solids will only be land applied as fertilizer after qualifying as Class A or Class EQ biosolids and if alternative markets for renewable energy fuels are not available at competitive prices. The distribution of concentrated nutrients and activated biochar is dependent upon the nutrient and mineral composition of the products with potential outlets being agriculture, soil amendments, renewable fuels, activated carbon, water and air purification and adsorbent filter materials.

Ecoremedy provides a major reduction in odors compared to most other approaches to waste management such as composting, landfill, anaerobic digestion, and land application.

From 2010 to 2014, Ecoremedy operated a full-scale R&D facility at Harrisburg Area Community College in Pennsylvania. We processed wastes such as composted biosolids and livestock manure on a campus with ten thousand students with no odor complaints during the four years of operations.

How did we achieve this?

On subsequent commercial projects, we have continued to uphold high standards for odor management.

After all, we go to work every day in these facilities and want a nice working environment for ourselves.

Activated biochar is charcoal created from organic forms of carbon such as wood, biosolids, or agricultural residue. It is one of three solid outputs that Ecoremedy can generate from biomass and is increasingly recognized around the world as a valuable product across many industries. For more information, visit our Resource Recovery page.

Ecoremedy can produce activated biochar at different temperatures and dwell times creating different filtration, adsorption, and agronomic properties. Ecoremedy is working with world-class researchers and industry-leading companies to create designer activated biochar products for specific industrial and agricultural applications.

Absolutely!

Ecoremedy can tailor each project to the goals of the client, including design/build options (with and without operating contracts) for those clients wanting to own their solution. Ecoremedy will also consider building, owning, and operating the facility with a long-term, fixed-fee, waste disposal contract with the waste producer. Under either scenario, Ecoremedy can provide a cradle-to-grave solution for your waste disposal needs for decades to come.

Current residuals management is reliant upon unsustainable practices such as landfilling, incineration, and out-of-state hauling of high-moisture solids to distant land application sites. Existing incinerators are steadily being phased out and are not being replaced due to insurmountable costs associated with emission controls to meet current environmental standards. The number of landfills accepting sludge has reduced significantly over the last few decades, and permitting landfill expansions or construction of new landfills is very challenging. Most US landfills are nearing capacity and most experts agree that the future of waste is not in landfills.

Many municipalities are facing diminishing outlets for land application due to lack of public support, lack of agricultural land near dense urban populations, climates that are not conducive to agriculture, and low fertilizer prices that do not justify long-distance hauling. States like Florida and California are increasingly banning the practice across entire regions. In 2016, 63% of New Jersey’s biosolids were either incinerated or landfilled instead of beneficial use.

Anaerobic digestion achieves a low reduction in solids volume and produces a wet, odiferous material that requires further treatment. Alkaline stabilization of digestate or dewatered sludge produces a net INCREASE in biosolids volume and results in a wet, low-nutrient product requiring nearby proximity to land application, a solution that is not sustainable.

Drying typically uses large amounts of unsustainable fossil fuels to produce dried residuals for which there is low demand, especially when large volumes are created.

Composting faces challenges due to costs, problematic odors, a large facility footprint, a large carbon polluter footprint, the low price of the final product, and limited demand.

Animal manure management faces many of the same challenges.

The Ecoremedy gasification process disrupts conventional treatment/disposal solutions by siting a treatment solution at the source of the waste production, thereby reducing truck traffic by approximately 90%, using the energy contained within the waste to fuel the evaporation process, and producing valuable products that are in high demand.

Typically, 40-50% of the budget for municipal wastewater treatment facilities is spent on biosolids management. In many areas of the country, those costs have been rising steadily with no end in sight for future increases.

While every project is different, Ecoremedy can often provide long-term fixed-fee solutions:

The Ecoremedy modular design, small footprint, low construction complexity, and rapid installation time improve cost-effectiveness through reduced staff time needed for project development, and reduced costs from construction and engineering services.

Operating costs are low compared to all conventional means for biosolids treatment. The equipment is mostly automated and does not require operators to have advanced skills.

Using our standard equipment configuration, Ecoremedy can process 14-68 wet tons per day of waste on a footprint of about 100′x65′ (every project is different).

Due to the modular nature of the Ecoremedy solution, scaling up throughput does not require a larger system. Instead, Ecoremedy simply increases the number of units in parallel to achieve the necessary throughput. If space is limited, the units can be arranged in a vertical configuration to reduce the footprint.

The Ecoremedy modular approach avoids problems that can arise with scaling and dramatically reduces construction complexity on larger projects. Furthermore, operational redundancy ensures extremely high plant availability.

Ecoremedy can produce mobile and/or containerized turnkey systems to meet client needs.

Unique to the waste gasification industry, the Ecoremedy solution runs 24-7 using the incoming waste as-is, without any additives like wood chips or fossil fuels, as the sole source of thermal energy.

The Ecoremedy solution uses parts and components that are readily available "off-the-shelf" from established U.S. suppliers, so there is no need to worry about the availability of parts.

With a purchase order or DBOOM contract in hand, Ecoremedy can deliver a project that is operational in as little as six months, depending on the size and complexity of the project. Rarely will an Ecoremedy project require more than 12 months to achieve commissioning from the date of a signed contract.

Based on decades of experience with gasification of intractable waste feedstocks, Ecoremedy does not take the approach of generating syngas for direct use in generators or for distribution of commercial-grade natural gas. This introduces unnecessary technology risk and complexity while dramatically inflating project costs.

Ecoremedy uses thermal energy from biomass feedstock that can be utilized in many ways, including generating steam that powers a steam-cycle turbine generator in a combined heat and power system.

First, Ecoremedy uses the thermal energy for the energy-intensive process of drying. Drying is necessary to prepare the feedstock for further use as fertilizer, activated biochar, or a solid fuel. In most cases, there are far more potential BTUs in the feedstock beyond what is needed for drying. The greater the moisture content, the more BTUs needed for drying.

From there, the best approach to utilizing the dry solids depends on the goals of the project. Ecoremedy can add a steam boiler to the project and use the dried solids as a renewable solid fuel with the same energy density as low-grade coal.

The steam can be used in many ways, including:

Ecoremedy provides a carbon-neutral, sustainable fuel source for drying waste feedstocks. Drying is necessary to prepare the feedstock for further use as fertilizer, activated biochar, or a solid fuel.

A wastewater facility serving a fairly small city might produce 15 tons per day of sludge that is dewatered to 25% solids. If the sludge is hauled off-site by truck, that’s 7,500 pounds of dry solids mixed with 22,500 pounds of water. About 3 million BTUs are required for drying 1 ton of water. Therefore, completely drying the solids requires about 34 million BTUs per day.

The precise amount of potential thermal energy (BTUs) of any waste feedstock is project-specific and requires testing to ascertain.