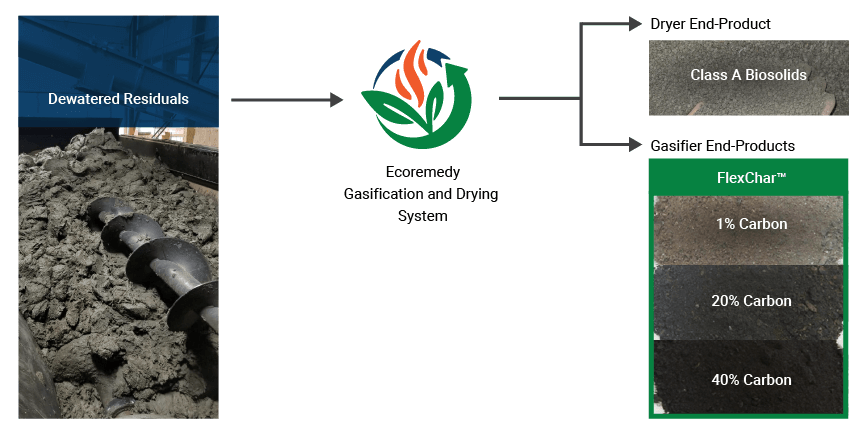

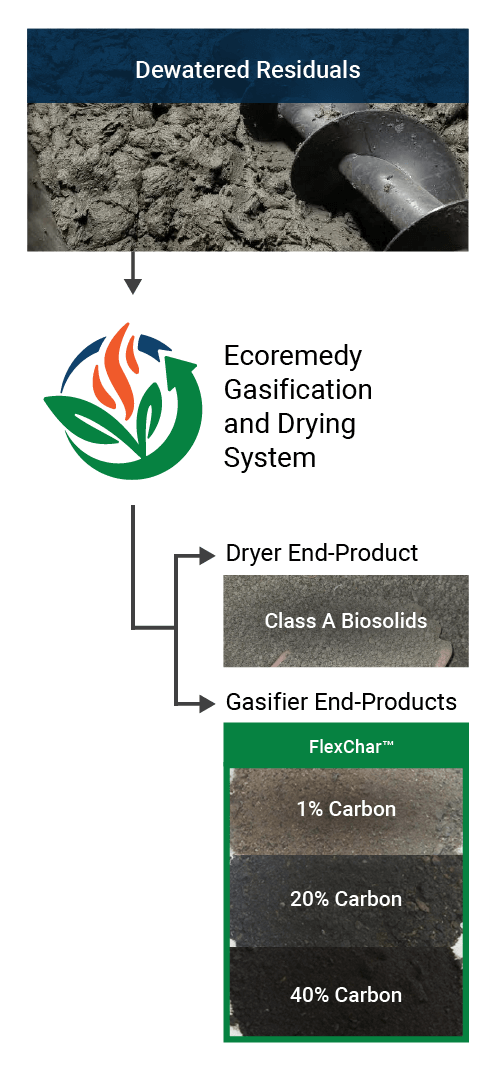

The Ecoremedy® Fluid Lift Gasification™ technology allows operators to switch in real-time between three different modes:

Using energy from the Fluid Lift Gasification process, the rotary drum dryer produces low-dust, Class A biosolids. This product meets EPA standards for land application with no restrictions and can be used as an alternative renewable fuel.

All dried material is returned to the process for maximum reduction to Low-Carbon FlexChar™ and maximum renewable energy recovery. This reduces incoming waste volume by over 95%, which reduces truck traffic and landfill costs.

Using energy from the Fluid Lift Gasification process, the rotary drum dryer produces low-dust, Class A biosolids. This product meets EPA standards for land application with no restrictions and can be used as an alternative renewable fuel.

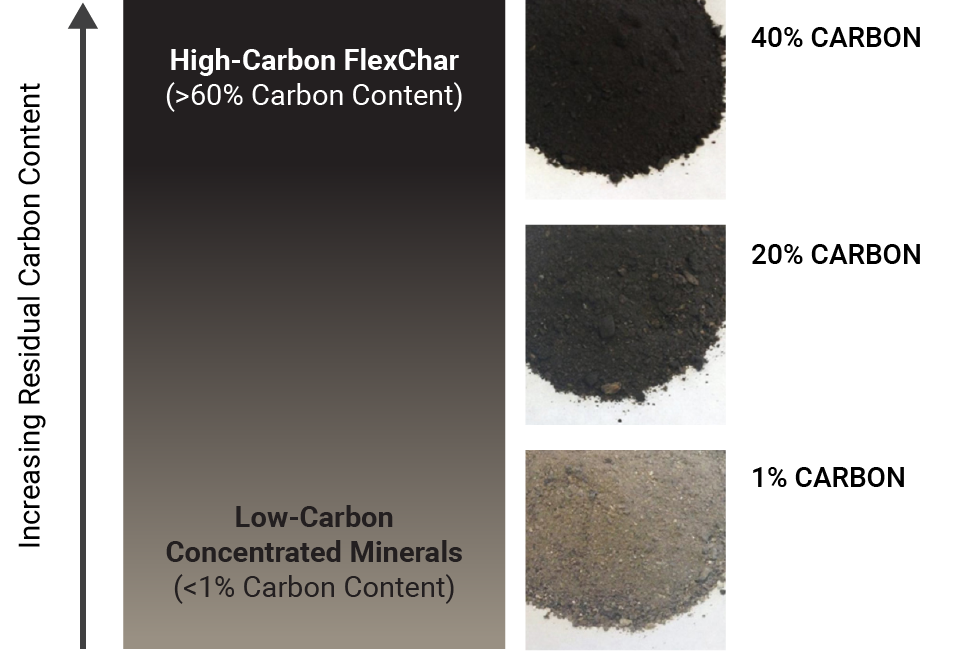

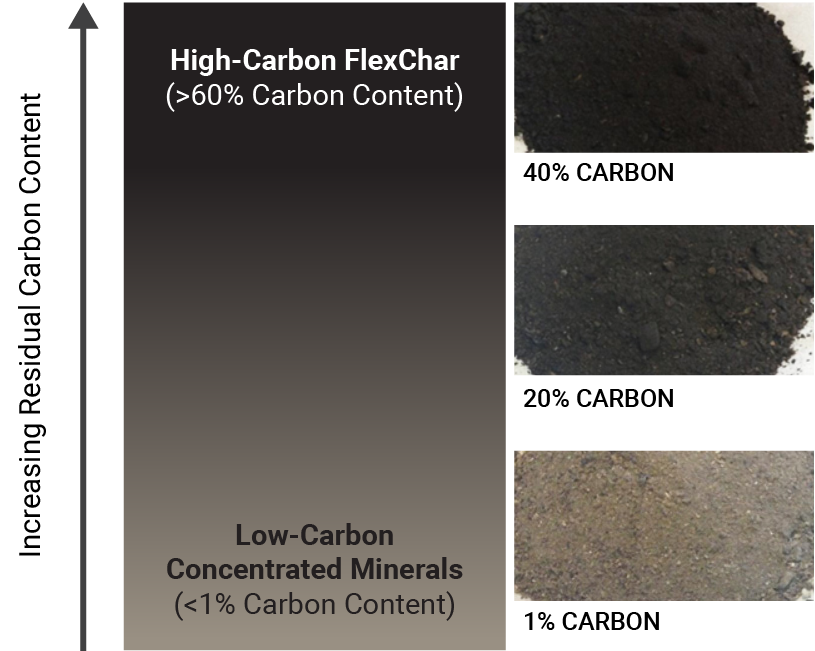

REAL-TIME TAILORED CARBON CONTENT

By adjusting residence times and oxygen levels in the gasifier, Ecoremedy offers the unique ability to balance energy recovery and the carbon content of FlexChar.

This allows our customers to accommodate changes in seasons, regulations, energy costs, and development of biochar markets over the 25-year life of a project.

For decades, Ecoremedy’s end-product flexibility has empowered our customers to recover resources from waste.

Ecoremedy recovered nutrients from poultry litter outperformed commercial fertilizer in a head-to-head growth study with the test plot being in marginal soil conditions.

PhD agronomist from the USDA confirms the outstanding results of Ecoremedy nutrients.