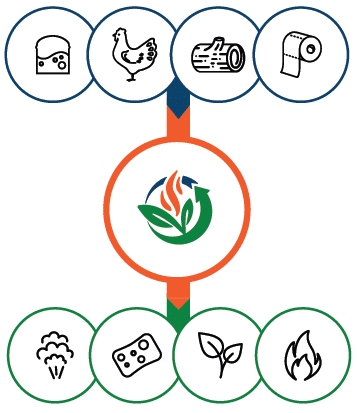

The Ecoremedy® Fluid Lift Gasification™ process thrives on the world’s most challenging organic feedstocks.

Over a decade of R&D and operating history has proven the ability of Ecoremedy to gasify a broad range of materials. We’ve focused on wastes that have proven to be problematic for other technologies.

Our systems deliver proven volume reduction, nutrient conversion, and energy recovery to municipal, industrial, and agricultural projects worldwide.

The Environmental Protection Agency (EPA) is issuing this rule after reviewing extensive research and science on how PFAS affects public health while engaging with the water sector and state regulators to ensure effective implementation. EPA also considered more than 120,000 comments on the proposed rule from a wide variety of stakeholders. More details about the final PFAS drinking water standards. For PFOA and PFOS, EPA is setting a Maximum Containment Level Goal – a non-enforceable health-based goal – at zero.

Continue ReadingEcoremedy’s Fluid Lift Gasification™ system at the Edmonds, Washington wastewater treatment plant is now producing FLG Sand™, which results when biosolids are processed in the gasifier. The material meets the criteria for Class A biosolids. It can be used as a stand-alone sand product or blended to produce high quality topsoil. The sand provides granularity that improves aeration and drainage. More than 50 billion tons of sand are used annually in the construction industry.

Continue Reading